| The Proper Installation of the Giberson Head |

| Ideas Concerning the Best Burner Port Design for the Giberson Ceramic Head. |

| This page is designed to give you hints on how to get good life out of your Giberson Ceramic Burner Head (2-3 years is the average life). I have a burner tip in my glory hole which is 25 years old and many people have burners that typically last for ten years, outlasting several furnaces. Still going strong! And this can be your story if you pay attention to a few of these ideas presented on these pages. |

| Please note that I promise only two things. First, the burner you buy today was personally cast by me. By this I mean I make them with my own hands, the same as I did 30 years ago. And Second, sooner or later the head will break. Some people will drop it and break it on opening the package. Others have broken them by hammering on the pipe work, brand new. (Don't do that!) Still others get burner "pop-back" or "burn-back" on the initial firing because they don't understand what "pop-back" is. And with this condition in place they turn up the gas and ruin the head. Click here for troubleshooting burner pop-back. |

| However, 95% of the installations go along with none of the hair-pulling problems just suggested. Having a trouble-free site is our primary aim. Please look over the following material. If you follow the suggestions below, you will have the best chance for a trouble free studio. |

| We begin by showing a worst case scenario. This is a situation which has killed many a good Giberson Tip. The Giberson Tip is not made out of super "god" material. It is subject to expansion and contraction. And just like crucibles, sooner or later the Giberson Burner Head will crack and fail and need replacement. But this is a sure killer, the narrow, long burner port shown at the right: |

|

|

| This straight burner port cracks heads because of the intense and rapid heat that builds up. The only situation worst than this is the "all-frax" burner port. It is general practice to turn on a glory hole and expect to have the unit at working temperature within 30-45 minutes, maybe an hour. But an all frax glory can get to temperature in 20 minutes. If the burner port is made of frax and is especially long, like our example here, then we get this rapid and intense heat build up just in front of the head which occurs within a couple of minutes. That's too hot, too fast! And that spells "trouble!" So with this "bad" idea on the page, let's explore some other ideas that promote burner head longevity. |

|

| Check List of Essentials for a Good Installation: |

- The burner Head is 4" in diameter and the burner block (or burner port) should be 4-1/2" in diameter. This leaves a 1/4" space on all sides of the head.

- Place the front of the head about 1/2" into the burner port.

- The burner is designed to be sealed into the burner block. To seal the head into the port I use a piece of "frax" that is 1/2" square X 14" long. Soak it in water and apply about one tsp. of Sairset mortar on the frax strip. In this wet condition the frax will compress and pack in the small space between the head and burner port. This will be a somewhat flexible gasket when the small amount of mortar hardens.

- Do Not Cover the head with Fiberfrax. The head needs to be exposed to the cool air.

|

|

|

|

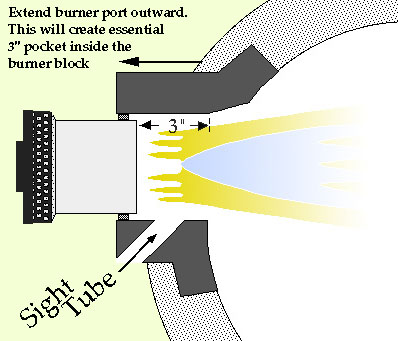

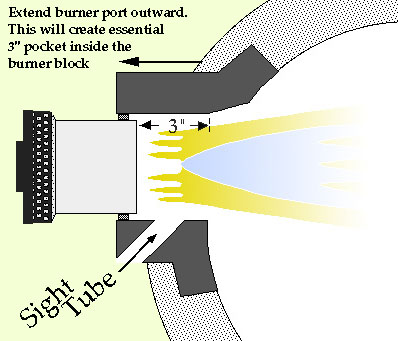

| Typical Glory Hole Installation: |

|

| On a narrow, thin walled installation such as this glory hole in a barrel, the burner block can be extended outward to accommodate the necessary design elements. Here in the space in front of the burner head there is a pocket of at least 3" deep to help the flame seat properly. This is also the UV sight target (about 3-4" in front of the head). |

|

| Installation of burner in thick walled furnace: |

|

| On a thick walled furnace structure, it is possible to inset the burner block as shown above. This allows most of the heat to move easily into the combustion chamber where the heat is needed. It also makes the burner head less obtrusive (sticks out less). |

| If you have any further questions please call Dudley Giberson (603) 456-3569 |